The Manual Handling Operations Regulations define it as 'any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or by bodily force'.

In effect, any activity that requires an individual to lift, move or support a load, will be classified as a manual handling task.

What are the risks of manual handling?

More than a third of all reportable injuries of over three days involve manual handling, and around 10% of major injuries are linked to manual handling. It has a major impact on all workplaces, and costs the economy hundreds of millions of pounds every year.

In the UK, 1.1m people reported that they suffered from musculoskeletal disorders (MSDs) caused, or made worse, by work. It is estimated 12.3m working days are lost annually due to work-related MSDs.

Anyone involved in the moving and handling of goods and people could be at risk. Injuries and suffering can be linked to any work involving handling of loads. There are risks in handling even light loads if a repetitive task is being carried out in poor conditions. Poor ergonomics and workplace layout are a factor in many hazardous manual handling tasks.

Risks can be found in all work sectors, but healthcare, agriculture and construction are recognised as high-risk industries due to the number and nature of the manual handling activities.

Legal duties and obligations around manual handling

The Manual Handling Operations Regulations

These Regulations state that employers should adopt a hierarchy of control measures:

to avoid hazardous Manual Handling Operations so far as is reasonably practicable

to assess any hazardous Manual Handling Operation that cannot be avoided

to reduce the risk of injury so far as is reasonably practicable.

To view the full text of the above legislation online, please follow the links under Legislation.

Assessing manual handling risks

One way to assess manual handling activities is to look at four specific areas - Task, Individual, Load and Environment (easily remembered by the acronym TILE).

As with any assessment, the workforce should be involved in the process, and use should be made of any relevant guidance available for particular industries.

Key factors to consider in each element are:

1. The Task

Does the activity involve twisting, stooping, bending, excessive travel, pushing, pulling or precise positioning of the load, sudden movement, inadequate rest or recovery periods, team handling or seated work?

2. The Individual

Does the individual require unusual strength or height for the activity, are they pregnant, disabled or suffering from a health problem. Is specialist knowledge or training required?

3. The Load

Is the load heavy, unwieldy, difficult to grasp, sharp, hot, cold, difficult to grip, are the contents likely to move or shift?

4. The Environment

Are there space constraints, uneven, slippery or unstable floors, variations in floor levels, extremely hot, cold or humid conditions, poor lighting, poor ventilation, gusty winds, clothing or Personal Protective Equipment that restricts movement?

Guideline weights for lifting and lowering

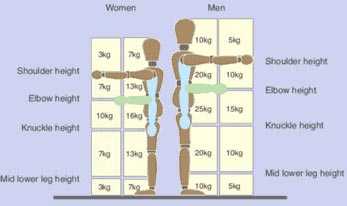

The chart below gives guideline weights for lifting and lowering, which assumes that the handling is taking place in reasonable working conditions with a load that is easily grasped with both hands by a reasonably fit, well-trained individual.

No manual handling activity is completely safe. However, using these guidelines as part of a well thought out risk assessment will reduce the risks from manual handling activities.

Weights to be lifted may need to be reduced below the guideline values if there are environmental or other factors that could have an adverse effect on the activity or if it involves twisting or bending.

Similarly, if the task is being carried out frequently then weights should be reduced.

From Getting to Grips with Manual Handling: a short guide INDG143 (external site) (The Health and Safety Executive).

Controlling risks from manual handling

As with any other risk, if you can eliminate or avoid the risks from manual handling, this is by far the best option. You should try to remove as many of the constraints as possible to reduce the risks to as low a level as reasonably practicable.

An ergonomic approach is recommended - look at how the task can be fitted to the individual.

Consider whether mechanical handling aids could be used, this could range from a simple trolley or sack truck to more sophisticated aids such as conveyors or fork lift trucks.

If you cannot eliminate or mechanise the manual handling tasks, you must carry out a risk assessment where the task could present a risk of injury. You need to look at ways to reduce the risks to as low a level as reasonably practicable.

Basic principles of manual handling

There are some basic principles that everyone should observe prior to carrying out a manual handling operation:

ensure that the object is light enough to lift, is stable and unlikely to shift or move

heavy or awkward loads should be moved using a handling aid

make sure the route is clear of obstructions

make sure there is somewhere to put the load down wherever it is to be moved to

stand as close to the load as possible, and spread your feet to shoulder width

bend your knees and try and keep the back's natural, upright posture

grasp the load firmly as close to the body as you can

use the legs to lift the load in a smooth motion as this offers more leverage reducing the strain on your back

carry the load close to the body with the elbows tucked into the body

avoid twisting the body as much as possible by turning your feet to position yourself with the load.

Lifting and handling in teams

Team lifting needs to be co-ordinated properly. Try and make sure that those lifting are around the same height and build, make sure one person is responsible for giving instructions, etc.. Make sure that everyone lifts, moves off, stops and places the load down at the same time.

Lifting in teams does not mean that the weight of the load can be increased by 100% for each extra person in the team.

For example, for a lifting team of two people the load should only be increased by 70%.

This means that if the risk assessment decided that it was okay for one person to lift a load of 20kg, using two people would mean that the load should not exceed 34kg - not that it's okay to lift a load of 40kg.

More detailed information on team manual handling can be found on the Health and Safety Executive website via their Manual Handling Assessment Chart Tool (external site).

Handling aids

Mechanical handling aids can reduce the risk of injury when used correctly. Even simple aids such as trolleys, sack trucks and wheelbarrows can be used to move items and reduce the likelihood of injury.

It is better to push rather than pull, and to use body weight and leg muscles to do the work. Make sure the load is kept under control, particularly on slopes.

In some cases more sophisticated manual handling aids may be required.

Cranes, hoists, pallet trucks, conveyors and fork lift trucks are used extensively in many industries to eliminate manual handling.

It should be remembered that, although the handling aids will eliminate many of the manual handling risks, their use will introduce others and these risks must be assessed.

Another consideration is that regulations require that many of these items require a periodic statutory inspection on safety critical components.

For more information, please see our page on Lifting operations and equipment.